|

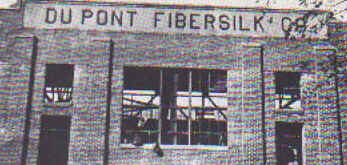

The Rayon Years

As many will know, the Old

Hickory site is older than 75 years. However, the record keepers

consider the date that rayon began production, January, 1925, as the

official date of the beginning of the DuPont-Old Hickory site.

The beginning and end of rayon stands testimony to the Old Hickory

site's ability to continually re-invent itself. As many will know, the Old

Hickory site is older than 75 years. However, the record keepers

consider the date that rayon began production, January, 1925, as the

official date of the beginning of the DuPont-Old Hickory site.

The beginning and end of rayon stands testimony to the Old Hickory

site's ability to continually re-invent itself.

In a special publication in 1950 noting 25 years of rayon

production at Old Hickory, the observation was made that the story of

rayon had a beginning and a middle, but no end. The demise of

rayon was in a future "too remote to foresee."

There was an end to DuPont's production of rayon, of course, but

not before the product, the plant, and the people at Old Hickory had

established a record of highest quality that has carried into

today. Accomplishments of Old Hickory rayon were important to

the growth of the DuPont Company. They resulted in a better life

including a higher standard of living for thousands of Middle

Tennesseans. And, on another level, for many, many people

the rayon plant was destined to become a large part of their daily

lives and in later years, their memories. Rayon was made for

more than 36 years here, for many an entire working career, and it

will not be forgotten.

Rayon plant 1 started production in January 1925, only nine months

after ground was broken for plant construction, and plant 2 began the

following December.

The first year's production amounted to 2.1 million pounds, and

production rose to a peak of 52 million pounds in 1951. All

told, over one billion pounds of textile and industrial rayon were

produced at this location.

In the early years, most rayon output went into low-priced

underwear and hosiery. the thought of producing woven fabrics

from "artificial silk" was then mere fancy.

Those early yarns had neither the strength to withstand the weaving

processes, nor the uniformity and quality for making fabrics that

would compete with trade demands. This condition did not last

long. Determined technical people with the aid of operating

organizations made rapid strides in gaining know-how and introducing

process improvements. As progress was made in such areas as

improving the dyeing properties of the yarns and increasing strength

of the product, Old Hickory yarns were gradually introduced into the

weaving trade. These improvements proved advantageous for this

site through the years, particularly during the depression.

Although business declined in this period, most spinning machines were

kept running and layoffs were not as long lasting as in most other

businesses throughout the country.

In the 1940s rayon surpassed wool and silk in fiber consumption in

the United States. It came to be used in the finest of fabrics

and the choicest of garments, with applications in ties, evening

dresses, gloves, raincoats, draperies, ribbons and exquisite

upholstery fabrics. Rayon had evolved far beyond the "artificial

silk" of 1925.

Despite many advancements in the product, a declining sales pattern

began in 1952 which continued until the plant was closed down.

In 1953 it became apparent that textile rayon would never again enjoy

the populairty of previous years. Furthermore, by this time, Old

Hickory rayon was not as competitive as it had been due to quality and

package improvements made by other rayon producers in up to date

plants.

It was at this point that Textile Fibers management began a series

of studies directed toward preserving Old Hickory as a plant

site. One major objective was to minimize any possible negative

effect on employees, many of whom had been with the DuPont Company

since rayon startup. In addition, considerable attention was

given to developing plans which would restore DuPont textile rayon to

a better competitive position. By early 1956, a plan had been

developed which appeared attractive from both personnel and economic

viewpoints. This program proposed to:

- Modernize the rayon plant to improve overall quality and extend

its useful life as long as possible.

- Select appropriate new products for the site which would

supplement and gradually replace rayon. "Dacron"

was tentatively visualized at this time.

Demand for rayon continued low, and it was soon decided to

consolidate all production into plant 1. Part of the plant 2

unit was shut down in late 1957 and the remainder in 1958. The

overall modernization-consolidation program for the remaining plant

was completed by mid-1958, approximately the same time that employees

learned they would soon be producing the new fiber Dacron.

During this period (1956-1958) wage roll employment dropped from 2,200

to 1,300, but the quality improvements temporarily stabilized sales

and aided job security for the remaining employees.

Employment was relatively stable through 1959. Late that year

and in early 1960 some 200 wage roll employees were

recalled to begin training for Dacron and DMT startups.

In August 1961, with Dacron well into production and the future

again brightening, Old Hickory people manufactured their last

rayon. An era had ended.

From Our Old Hickory Heritage -

published by the DuPont Old Hickory Site, 1982.

Return to Top.

|